PolydiEthylsiloxane fluids (PES)

Organosilicon liquids are a group of highly effective oligomeric substances with a set of properties inherent only in this class of polymeric compounds and not repeated in any other currently known natural or synthetic materials.

It is used as a component in the production of oils, lubricants, including plastic (coherent).

PES improves the low-temperature characteristics of hydrocarbons, lowers the pour point and maintains satisfactory viscosity at -50 ° C.

Chemically inert and physically inert, resistant to corrosion, explosion-proof, hardly flammable, does not irritate the skin and mucous membranes.

Fully compatible with mineral and synthetic oils, well compatible with antioxidant and antifriction additives, synthetic hydrocarbons, fats, vitamins, paraffins.

They have high dielectric properties and increased radiation resistance, little dependence on the frequency of the electric field

Does not oxidize at temperatures up to plus 200 °C

High compressibility

PolydiEthylsiloxane fluids (PES)

Enter your phone number or e-mail and our specialists will contact you shortly

By clicking on the "Submit" button, you consent to the processing of personal data and agree to the privacy policy

Depending on the viscosity, PES are classified by application as follows:

Application

PES with a viscosity of 20 cSt or less (with a glass transition temperature of -40 °C) - usually used in electro-hydraulic pushers to drive automation mechanisms operating in the temperature range from -60 °C to +100 °C, for impregnating capacitors and filling piezoelectric sensors in the composition of polishing compounds as coolants; as working fluids in hydraulic systems.

PES with a viscosity of 40-50 cSt at 20 °C (with a glass transition temperature of minus 140 °C), they are a high-tech organosilicon liquid, a mixture of polyethylsiloxanes of predominantly linear structure with a boiling point above 190 °C at a residual pressure of 1.33 * 10² - 3.99 * 10² (1-3 mmHg). Used for the manufacture of greases and greases.

PES with a viscosity of 200-400 cSt are polydiethylsiloxanes with a boiling point above 250 °C at a residual pressure of 133-339 Pa (1-3 mm Hg). Designed for use as a working fluid of vane hydraulic shock absorbers, for operating temperatures from -110 °C to +200 °C.

All PES fluids mix well with mineral and synthetic oils and other organic products, they are used as a base for low-temperature tool and hydraulic fluids and oils, as damping fluids in devices, a dispersing medium in plastic and release lubricants, a component of polishing and cleaning compounds, lubricants in the production of synthetic fibers.

The addition of PES to hydrocarbons improves the low-temperature characteristics of the latter. Mixtures of PES with oils have a lower pour point and a satisfactory viscosity at -50 °C.

Polydiethylsiloxanes can be mixed with petroleum oils in any ratio to improve their lubricating properties. They are suitable for extreme pressure and anti-wear applications. They can be used alone or as mixtures. PES fluids are biologically and corrosively inert.

Low temperature tool oils, frost resistant lubricants and hydraulic filling fluids are formulated from mixtures of polydiethylsiloxanes and mineral oils.

Polydiethylsiloxane fluids are used as operating oil for diffusion vacuum pumps. They differ from organic vacuum fluids in their increased thermal-oxidative stability.

PES with a viscosity of 40-50 cSt at 20 °C (with a glass transition temperature of minus 140 °C), they are a high-tech organosilicon liquid, a mixture of polyethylsiloxanes of predominantly linear structure with a boiling point above 190 °C at a residual pressure of 1.33 * 10² - 3.99 * 10² (1-3 mmHg). Used for the manufacture of greases and greases.

PES with a viscosity of 200-400 cSt are polydiethylsiloxanes with a boiling point above 250 °C at a residual pressure of 133-339 Pa (1-3 mm Hg). Designed for use as a working fluid of vane hydraulic shock absorbers, for operating temperatures from -110 °C to +200 °C.

All PES fluids mix well with mineral and synthetic oils and other organic products, they are used as a base for low-temperature tool and hydraulic fluids and oils, as damping fluids in devices, a dispersing medium in plastic and release lubricants, a component of polishing and cleaning compounds, lubricants in the production of synthetic fibers.

The addition of PES to hydrocarbons improves the low-temperature characteristics of the latter. Mixtures of PES with oils have a lower pour point and a satisfactory viscosity at -50 °C.

Polydiethylsiloxanes can be mixed with petroleum oils in any ratio to improve their lubricating properties. They are suitable for extreme pressure and anti-wear applications. They can be used alone or as mixtures. PES fluids are biologically and corrosively inert.

Low temperature tool oils, frost resistant lubricants and hydraulic filling fluids are formulated from mixtures of polydiethylsiloxanes and mineral oils.

Polydiethylsiloxane fluids are used as operating oil for diffusion vacuum pumps. They differ from organic vacuum fluids in their increased thermal-oxidative stability.

Operating temperature limits for liquid PES: from -100 °С to +150 °С.

Differences between PES and PMS

- Polydiethylsiloxanes are transparent liquids with a viscosity of 1.5 to 1 × 106 mm²/s, depending on the degree of polymerisation. These liquids have significantly lower glass transition and solidification temperatures compared to polydimethylsiloxanes, but the effect of temperature on their viscosity is more significant. Polydiethylsiloxanes have a higher viscosity at 20 °C than polydimethylsiloxanes of comparable chain length. The main difference between polydiethylsiloxanes is the extremely low pour point, which is 1.5-2 times lower than that of polydimethylsiloxanes, and reaches minus 140 °C.

- Polydiethylsiloxanes under the PES brand dissolve easily in most organic solvents and, unlike other organosiloxanes, are fully compatible with mineral oils, which has led to their widespread use as a base for oils and greases.

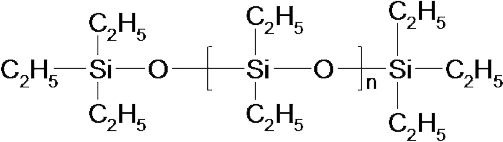

- Replacement of methyl substituents in organosiloxanes with ethyl substituents restricts the freedom of rotation of atoms and groups around Si-O- and Si-C≡ bonds. This leads to an increase in the rigidity of the chains and thereby prevents the realization of helical conformations of the siloxane chains and the complete intramolecular compensation of the dipoles of the polar bonds ≡Si-O-. The branched structure of some polydiethylsiloxanes has the same effect.

- On the other hand, ethyl substituents and branching prevent close packing of chains, which leads to large distances between chains in diethylsiloxanes compared to dimethylsiloxanes and to a decrease in intermolecular interactions.

- Polydiethylsiloxanes under the PES brand dissolve easily in most organic solvents and, unlike other organosiloxanes, are fully compatible with mineral oils, which has led to their widespread use as a base for oils and greases.

- Replacement of methyl substituents in organosiloxanes with ethyl substituents restricts the freedom of rotation of atoms and groups around Si-O- and Si-C≡ bonds. This leads to an increase in the rigidity of the chains and thereby prevents the realization of helical conformations of the siloxane chains and the complete intramolecular compensation of the dipoles of the polar bonds ≡Si-O-. The branched structure of some polydiethylsiloxanes has the same effect.

- On the other hand, ethyl substituents and branching prevent close packing of chains, which leads to large distances between chains in diethylsiloxanes compared to dimethylsiloxanes and to a decrease in intermolecular interactions.

Contacts

Sales department

620026, Russia, Yekaterinburg, Rosa Luxemburg st., 49

Tel .: +7 800 444-71-72

E-mail: oreferent@ahprom.ru

620026, Russia, Yekaterinburg, Rosa Luxemburg st., 49

Tel .: +7 800 444-71-72

E-mail: oreferent@ahprom.ru

Commercial Director

Elena Borisovna Suvorova

E-mail: a.suvorova@ahprom.ru

Petrochemicals and organosilicon

Evgeny Vyacheslavovich Enkov

Tel .: +7 958 134 46 87

E-mail: e.enkov@ahprom.ru

Elena Borisovna Suvorova

E-mail: a.suvorova@ahprom.ru

Petrochemicals and organosilicon

Evgeny Vyacheslavovich Enkov

Tel .: +7 958 134 46 87

E-mail: e.enkov@ahprom.ru

Production cort

658837, Russia, Altay Territory, Yarovoe, Predzavodskaya sq., 2

Tel .: +7 800 444-71-72

E-mail: oreferent@ahprom.ru

658837, Russia, Altay Territory, Yarovoe, Predzavodskaya sq., 2

Tel .: +7 800 444-71-72

E-mail: oreferent@ahprom.ru

Оставьте ваше сообщение и контактные данные, и наши специалисты свяжутся с вами в ближайшее время

Нажимая на кнопку "Отправить", вы даете согласие на обработку персональных данных и соглашаетесь c политикой конфиденциальности